Introduction

Competences

Engineering of automation systems.

Plant analysis and optimisation of automation system configuration.

Engineering of electrical plants.

Base engineering, detail engineering. Motor list, sensor list, cable list, etc... Engineering and development of PLC software and HMI based on SCADA software.

Functional descriptions.

PLC to PC networking and field networks for instruments and drives.

Engineering of level 2 software for quality control and process technological management.

Algorithms and variable analysis for quality control.

Functional description of level 2 functions.

Software development.

PLC software (Siemens, Allen Bradley,GE etc...). HMI screens based on SCADA software like WinCC ,Wonderware InTouch HMI, JMobile, Citect, GE Proficy Cimplicity etc... LAN networks configuration.

Services

The services offered by Celox di Dentesano Andrea are as follows:

Engineering activities.

On site activities.

Projects

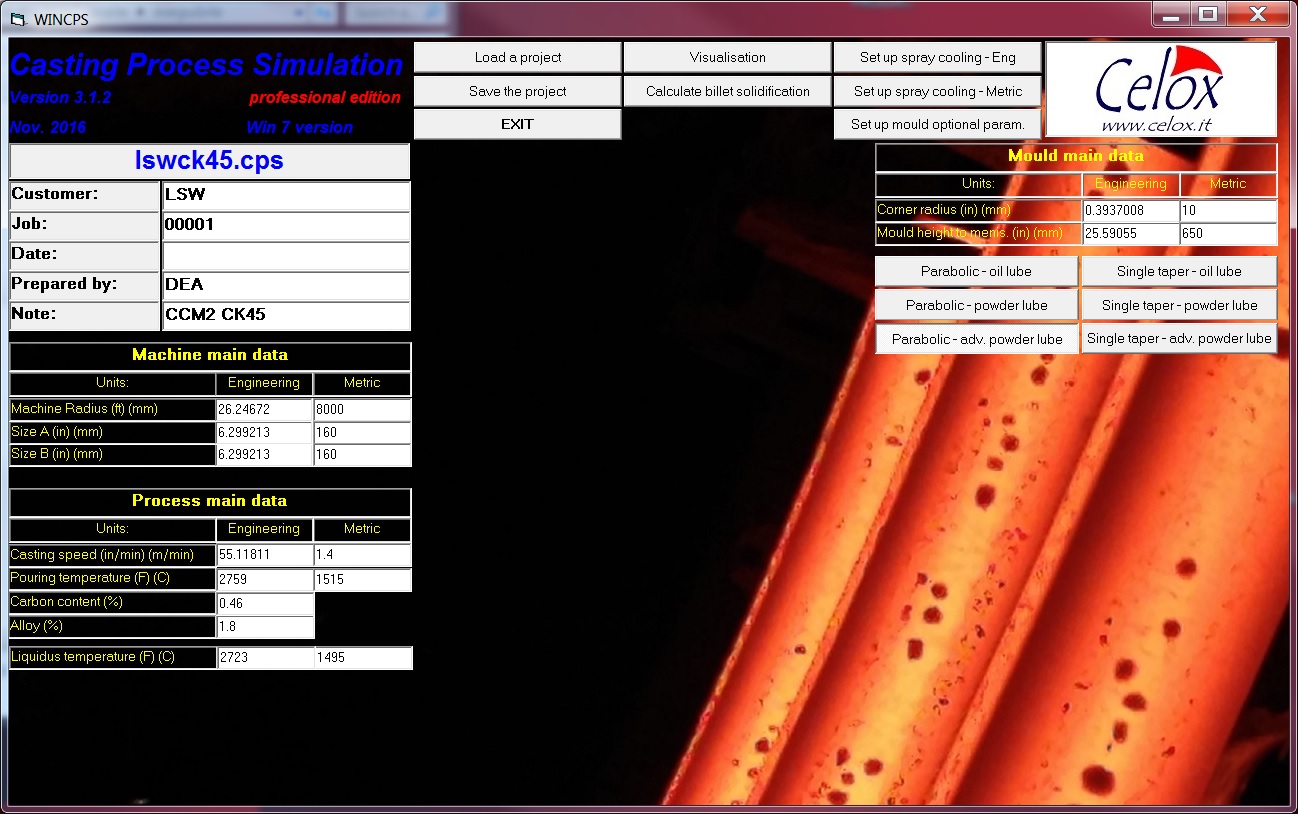

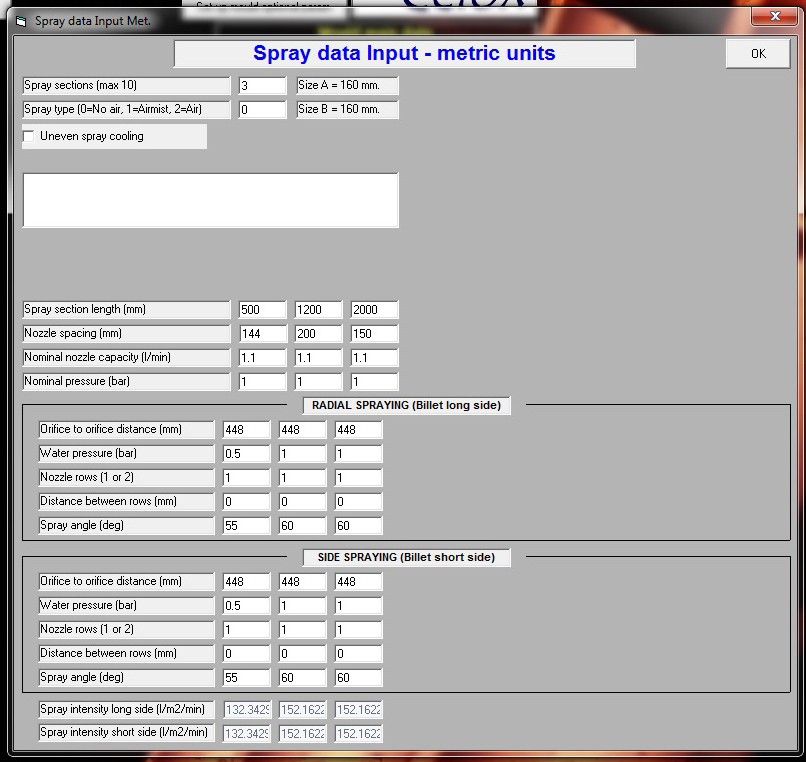

WINCPS

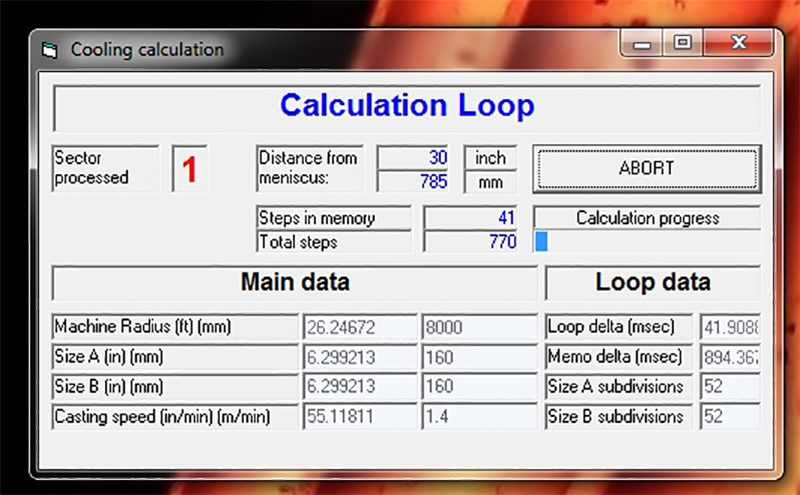

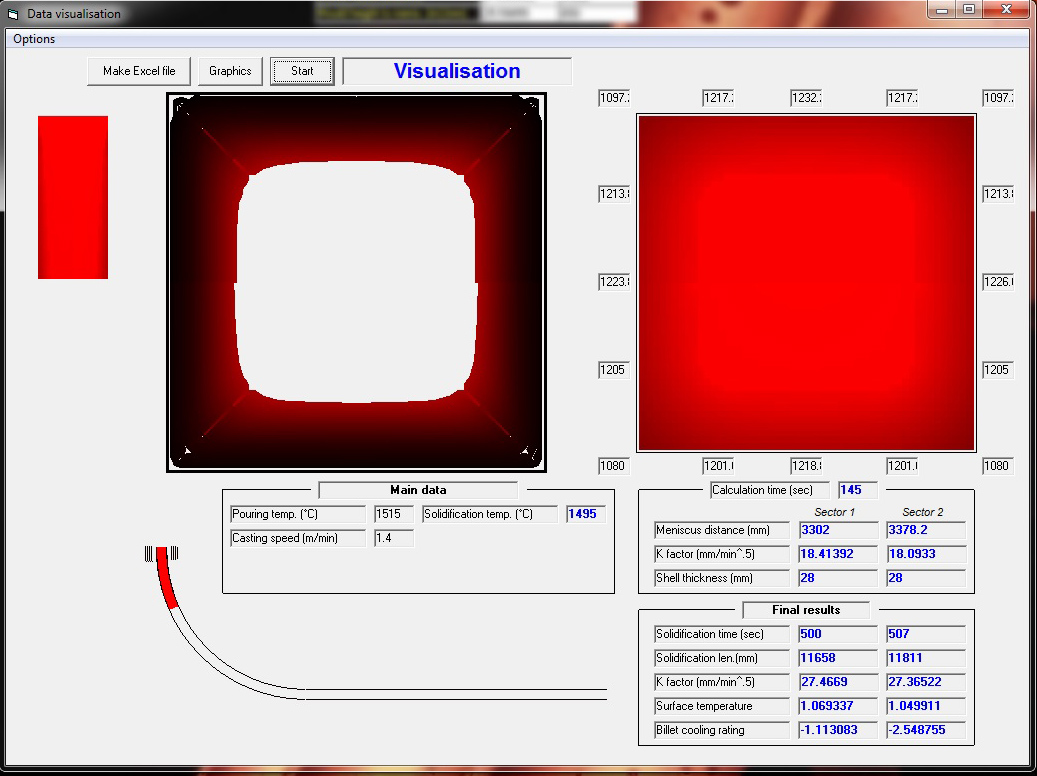

Casting Process Simulator for Windows

Product position

The Casting Process Simulator is a system, based on a sophisticated mathematical model, used for investigate the cooling process on billet and bloom continuous casting machines. It is applicable either on square product or on rectangular ones.

<

<